Applicants

8 solutions submitted

Participants

7 elegible solutions

Iberia

Duration

3 months

Overview

LL2FRESH is an online co-creation program that aims to optimize the shelf life of food. The program seeks innovative solutions to promote the development of innovative value chains, new packaging solutions, food treatment methods and state-of-the-art additives.

To find sustainable solutions to optimize the shelf life of food, LL2FRESH invited emerging Entrepreneurs / Researchers / Start Ups who work on transformational projects to participate in a European co-creation program.

LL2FRESH as a co-creation program selected 10 projects that defined a practical approach to reveal new solutions. For 3 months, projects had the opportunity to work together with companies and stakeholders to develop and demonstrate the value of their solutions.

The program selected three distinct projects that will receive advisory services and access to an exclusive network of stakeholders and experts, including a lump sum of 2,400 euros.

The program reached its goal to co-designed 5 solutions but the respond to the four integrated challenges did not get the expected attention. Close to the final pitch session, all LL2Fresh Stakeholders were invited to participate in an online Masterclass to boost their knowledge about Sustainability.

List of ideas that was worked on

The LLFRESH Co Creation Programme sought the most transformative ideas that address one or more of the following Challenges:

Packaging materials and structure: new materials that can guarantee resistance to handling, recycled and that guarantee the optimization of logistics processes. Effectively biodegradable packaging.

Conservation: Modified atmospheres. Technology for quantifying the quality of the packaged product.

Security/Communication: Technology to ensure food safety of packaged products. Information on product traceability.

Food Supply Chain and Business Model Innovation for Sustainable Agrifood: New marketplaces and new customer relationships value chains. Minimize the expiration food in retail and HORECA channels. Data driven food supply chain management.

Prizes

01

Team 1: Prize (2400€) + (40 hours of coaching, with a network of

experts)

02

Team 2: Prize (2400€) + (40 hours of coaching, with a network of experts)

03

Team 3: (2400€) 40 hours of coaching, with a network of experts

04

Team 4: 40 hours of coaching, with a network of experts

05

Team5: (40 hours of coaching, with a network of experts)

Co-creation programme

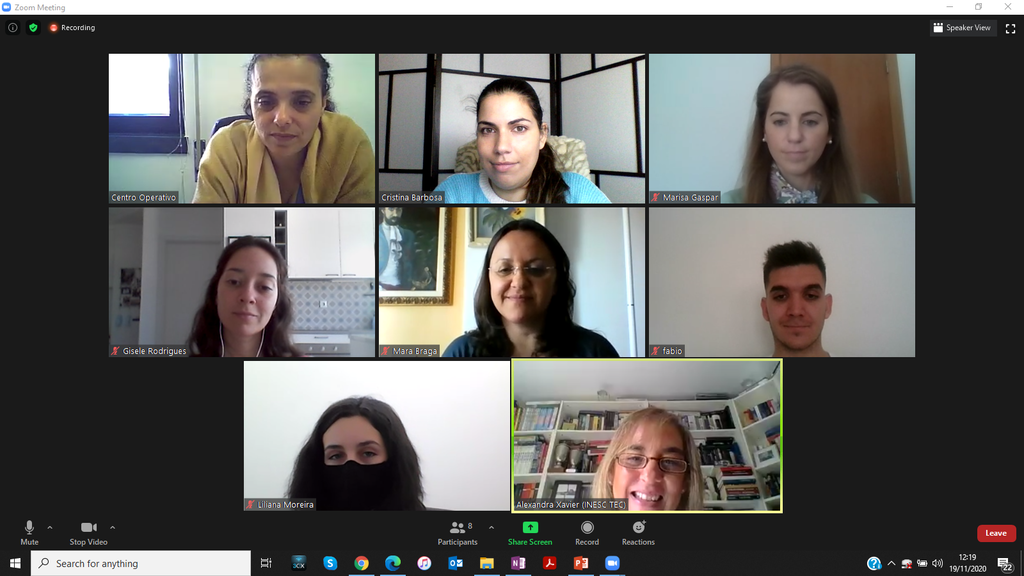

Organised by COTHN-CC: Centro Operativo Tecnológico Hortofrutícola Nacional

LONG LIFE TO SAFE FRESH- LL2FRESH

SAFE-pack: Sustainable and Antioxidant Functional Edible coatings and food packaging films

Team: Marisa da Costa Gaspar; Mara Elga Medeiros Braga

The main idea of the SAFE-pack team is to develop natural-based polymeric films and coatings with the inclusion of bioactive ingredients (e.g., antioxidants and antimicrobials) in order to obtain an edible film/coating that can be used as a packaging system. The main objective is, therefore, to develop sustainable systems that may extend the food shelf life and improve human health, by delivering the antioxidants to the organism. On the one side, this project aims at using natural materials, instead of synthetic ones, which usually are non-renewable resources and present environmental impacts. This work also intends to use residues from agro-food industry for obtaining the bioactives and the polymers. Thus, this approach will clearly contribute to the circular economy, in the biorefined context, improving the sustainability of the sector.

Mater dynamics - Stamply® Box

Team: Dr Tiago Cunha Reis, Drª Ana Machado e Gisele Rodrigues

Mater Dynamics's Stamply® Box is a smart food delivery box, which provides a cold environment thus avoiding the need for cold chain transportation. By being smart, each box can self-measure its internal conditions (Temperature and Humidity), while it can report its location. Our product is embedded with an unique digitally identifiable ID, allowing its traceability from producer to consumer. The Stamply® Box is compliant with common hardware (such as smartphones or tablets) through wireless protocols, being made of a resistant polymer that maximizes the product's life cycle and reusability. Our solution empowers small producers and brand owners to efficiently address new food-related distribution models. Data can be leveraged for better logistics, business operations and new UX models towards increasingly demanding consumers and regulators.

PREVSEG

Team: Pedro Dinis Gaspar, Ricardo Mesquita

The present project is based on the use of predictive microbiology models to determine the number of colony-forming units per gram (CFU / g) for various strains of bacteria, by measuring the temperature and relative humidity of the air inside refrigeration or freezing equipment in which food products are stored. Having knowledge of the bacterial strains that usually affect each type of food product, it is possible to predict when the number of CFU / g that makes this food harmful to human consumption is reached, that is, when the so-called minimum harmful microbial load is reached.

The system consists of a temperature and relative humidity sensor, a microcontroller and components responsible for data communication between the physical device and the interface associated with the predictive monitoring and control device for food safety.

The simplicity and size of the components used allow the external part of the device to be simple and small in size.

Nature preserves

Team: Liliana Moreira; Inês Brandão; Christophe Espírito Santo

Nature preserves is an aqueous extracts formula rich in phenolic compounds with antimicrobial and antioxidant effect, a naturally and sustainable way to preserve fruit and vegetables as fresh or processed product.

ELM-UBI

Team: Fábio Leitão; Pedro Dinis; Pedro Dinho

Innovation in temperature conservation in food product packaging: Introduce phase change materials in the alveoli of food product boxes, which dissipate energy and keep products close to ideal temperatures, maintaining their quality.